In the rapidly evolving world of rechargeable power, NMC (Nickel Manganese Cobalt Oxide) and NCA (Nickel Cobalt Aluminum Oxide) stand out as the two dominant chemistries. They power everything from the electric vehicle (EV) in your driveway to the drone in the sky.

While they share similarities, choosing the wrong chemistry can lead to suboptimal performance or safety risks. This guide breaks down the critical differences in energy density, power output, and longevity to help you select the right battery for your application.

What is an NMC Cell?

An NMC battery cell is a lithium-ion powerhouse featuring a cathode made of Nickel, Manganese, and Cobalt.

The magic of NMC lies in its versatility. Manufacturers adjust the ratio of these three elements to tune the battery’s performance:

- Nickel: High energy density.

- Manganese: Structural stability and safety.

- Cobalt: High energy and stability (though expensive).

Common Compositions:

- NMC 811: 80% Nickel, 10% Manganese, 10% Cobalt (High Energy)

- NMC 532: 50% Nickel, 30% Manganese, 20% Cobalt (Balanced)

- NMC 622: 60% Nickel, 20% Manganese, 20% Cobalt (Balanced)

What is an NCA Cell?

An NCA battery cell swaps manganese for Aluminum, utilizing a cathode of Nickel, Cobalt, and Aluminum.

NCA chemistry is engineered for one primary goal: Maximum Energy Density.

- Typical Composition: ~80% Nickel, 15% Cobalt, 5% Aluminum.

Key Differences: NMC vs. NCA

While both are lithium-ion technologies, their performance characteristics diverge in critical areas.

| Feature | NMC (Nickel Manganese Cobalt) | NCA (Nickel Cobalt Aluminum) |

| Energy Density | 150 – 220 Wh/kg (Standard) (Note: Advanced NMC can reach 350 Wh/kg) | 200 – 260 Wh/kg Generally higher density per kg. |

| Thermal Stability | High. Manganese provides excellent structural integrity during heating. | Moderate. Requires sophisticated battery management systems (BMS) for safety. |

| Cycle Life | Long. typically outlasts NCA in total charge/discharge cycles. | Moderate/Good. Excellent for performance, but degrades slightly faster. |

| Cost | Moderate. Lower cobalt content in newer mixes reduces price. | High. Cobalt and complex manufacturing increase costs. |

| Best For | Power tools, E-bikes, Medical devices, standard EVs. | Long-range EVs (Tesla), Aerospace, High-end electronics. |

1. Energy Density

Traditionally, NCA held the crown for energy density (200-260 Wh/kg). However, the gap is closing. Leading manufacturers like Grepow have engineered advanced NMC battery cells that push boundaries, achieving energy densities of up to 350 Wh/kg, rivaling and even exceeding standard NCA performance.

2. Thermal Stability & Safety

If safety is the absolute priority, NMC often wins. The presence of manganese lowers the battery’s internal resistance and makes it more resistant to thermal runaway. NCA cells, while safe with proper management, are chemically more volatile and require robust cooling and management systems.

3. Cycle Life

For applications requiring years of daily service, NMC is generally the superior choice. Its chemical structure allows it to withstand more charge and discharge cycles before significant capacity loss occurs compared to NCA.

Use Cases: When to Choose Which?

Applications for NMC Batteries

NMC is the industry standard for “balanced” performance. It provides high current (power) and decent capacity (range).

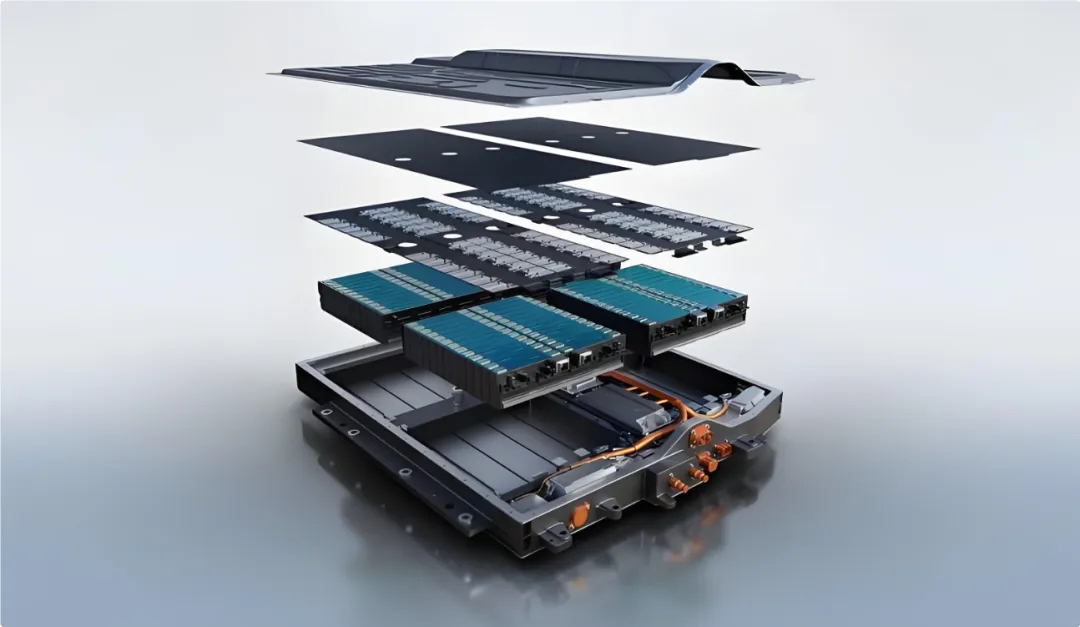

- Electric Vehicles (EVs): Used by nearly every major automaker for standard-range and performance vehicles.

- Medical Devices: Reliable power is non-negotiable for portable defibrillators, infusion pumps, and patient monitors.

- Power Tools & E-Mobility: E-bikes and cordless tools rely on NMC for the ability to deliver high power bursts without overheating.

Applications for NCA Batteries

NCA is the specialist choice for when you need to maximize run-time and minimize weight.

- High-Performance EVs: Pioneers like Tesla famously utilize NCA chemistry to achieve industry-leading driving ranges.

- Drones and UAVs: Long-endurance drones benefit significantly from NCA’s high specific energy, allowing them to stay airborne longer with less battery weight. (Note: While some high-discharge racing drones use NMC, long-range mapping drones favor NCA or high-density NMC).

- Aerospace: In satellites and aviation where every gram counts, the superior energy-to-weight ratio of NCA is critical.

- Consumer Electronics: High-end laptops and smartphones often use NCA to maximize battery life in slim form factors.

Conclusion

The choice between NMC and NCA comes down to your project’s specific “Pain Points”:

- Choose NMC if: You need a cost-effective, safe, and durable battery that balances power and energy. It is the versatile workhorse for most modern electronics and EVs.

- Choose NCA if: Your priority is maximum range or run-time and you have the budget and engineering capacity to manage thermal constraints.

Understanding these chemical nuances ensures you don’t just buy a battery—you invest in the right power solution for your technology.

Frequently Asked Questions (FAQ)

Is NMC better than NCA? It depends entirely on your application. NMC (Nickel Manganese Cobalt) is generally considered the “better” all-rounder because it offers an excellent balance of safety, cost, and lifespan. It is the go-to choice for power tools and standard electric vehicles. However, if your project requires maximum range and energy density (like high-performance EVs or aerospace tech), NCA (Nickel Cobalt Aluminum) is the superior choice.

Which battery has a longer cycle life, NMC or NCA? Typically, NMC batteries offer a longer cycle life. The inclusion of manganese in the cathode chemistry adds structural stability, allowing the cell to withstand more charge and discharge cycles before degrading. While NCA technology is improving, NMC remains the leader for longevity.

Why do some electric vehicles (like Tesla) use NCA instead of NMC? Automakers that prioritize range often choose NCA because of its massive energy density (200-260 Wh/kg). This allows the vehicle to travel further on a single charge without needing a physically larger or heavier battery pack. However, many manufacturers are now moving toward advanced NMC blends (like NMC 811) to bridge this gap.

What are the main disadvantages of NCA batteries? The two main drawbacks of NCA cells are thermal stability and cost. Chemically, NCA is more volatile than NMC and requires sophisticated Battery Management Systems (BMS) to monitor heat and prevent thermal runaway. Additionally, the raw materials (specifically Cobalt) and complex manufacturing processes often make NCA cells more expensive to produce.